Operation process

1. Pretreatment process

Dye guide agent: 1-5% (usually fabric weight, light colors can be reduced)

Soda ash: 8-10%

First, add cold water to the dyeing machine, put the finished clothes that need to be dyed into the machine, add a dye guide for 10 minutes, add soda ash for 10 minutes, gradually raise the temperature to 55-60 degrees, and after 30 minutes of treatment, drain the water and clean with cold water twice

2. Dyeing process

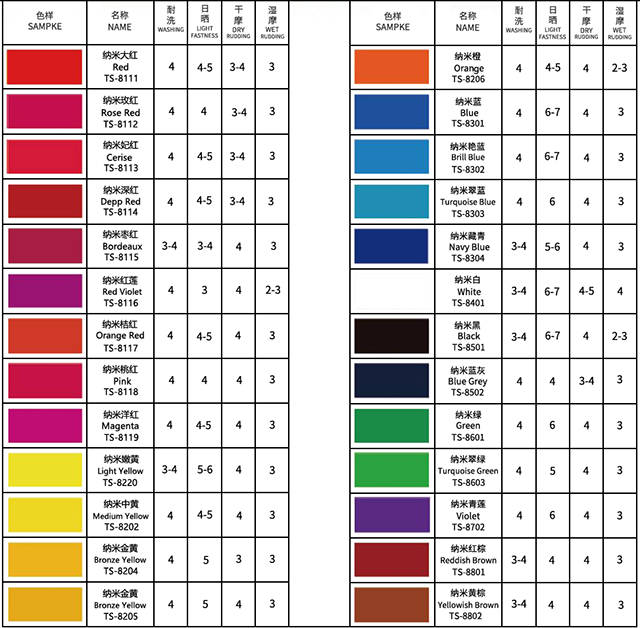

Blue grain color paste: X% (dosage depends on color)

Solidification: 1-5% (same dosage as dye guide)

First, put cold water into the dyeing machine, add the color paste and treat for 10 minutes. Gradually raise the temperature to 70-80 degrees Celsius and treat for 30 minutes. Drain the water and rinse with cold water twice. When the fastness requirement is high, add the solid slurry and warm water for 10 minutes to fix the color, and then discharge the water and dry it out of the machine. (Good dry fastness after drying)

3. Enzyme washing

4. Soap washing

(Wash with soda ash soap and hot water for 10 minutes), soften, dehydrate and dry

Packaging and storage

1. 50kg/barrel, with built-in plastic bag and paper barrel packaging

2. Store tightly at room temperature