Application process

Product |

Temperature(° C) |

pH |

Dosage and equipment (rope dyeing machine, jet dyeing machine, etc.) |

Compound refining enzyme |

50-60/80 |

6.0 -& Nbsp; 8.0 |

1-2% by fabric weight |

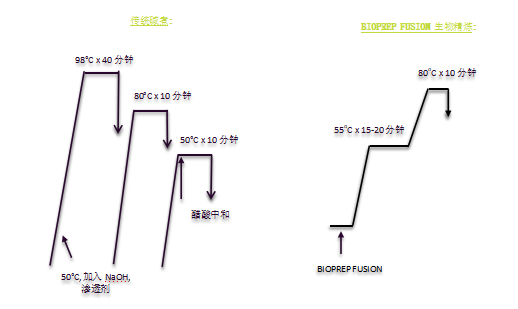

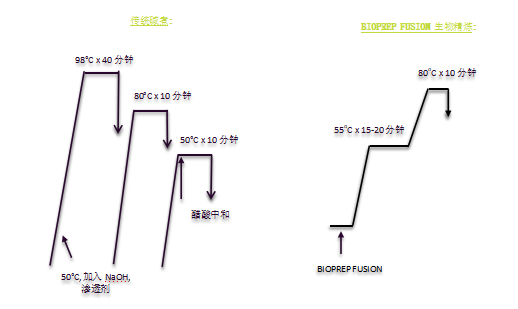

Comparison of typical processes (Figure 1)

Figure 1 Comparison of Traditional Alkali Cooking Process and Biological Refining Process of Composite Refining Enzymes for Typical Knitted Fabrics in Jet Dyeing Machines

The use of composite refining enzymes does not require the addition of additional additives, such as penetrating agents, defoamers, etc.

If chelating agents such as chelating agents, dispersants, and water softeners are used in the alkaline cooking process, then biological refining

Equal addition and use are also required in the process

Comparison of treatment effects between traditional alkaline cooking process and composite refining enzyme refining process

Alkali boiling process

Comparison |

Compound refining enzyme

|

pH |

6-8 |

13-14 |

Temperature |

50/80 ° C |

95-100 ° C |

Pectin residue rate |

< 15% |

10-15% |

Weightlessness |

< 3% |

3-8% |

Moisture absorption, drip test |

< 1-3 Seconds |

< 1-3 Seconds |

Breaking strength,% compared to before treatment |

90-100% |

85-95% |

Oxygen bleaching performance |

Same |

Dyeing performance |

Dark and medium depth colors have the same effect |

Wet rubbing fastness |

Same |

Water washing fastness of multi fiber cloth |

Same |

COD |

60-70% |

100% |

Compounding

Composite refining enzymes are ready-to-use products

Security, operation, and storage

Provide guidance on safety, operation, and storage for all products